What is Delta Automation?

In the fast-evolving landscape of digital printing productions, automation is quickly evolving from novelty to necessity. Automating print production to streamline processes from customer input to print output saves manual work, time and eliminates potential error sources, drastically reducing production costs in the process.

With <delta> Automation, ErgoSoft offers a solution for automated processes to interact with ErgoSoft RIP, the premiere digital printing solution in the RIP software market, allowing it to be integrated into fully automated workflows from customer order to finished print output.

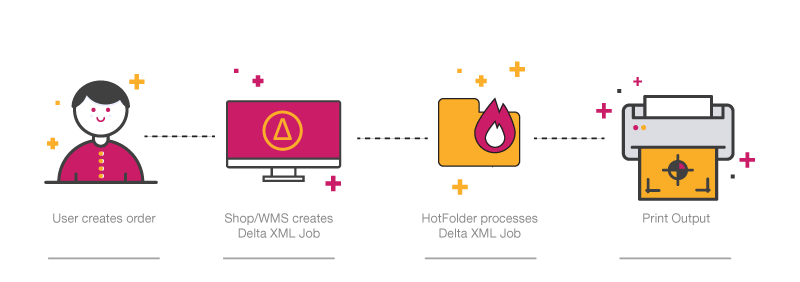

With <delta> Automation, print jobs can be supplied to the ErgoSoft RIP through a set of XML instructions telling the RIP exactly which image to print with what parameters.

Interfacing applications can dynamically generate these instructions when an order comes into the system, making it possible to launch a print run without any operator interaction.

How exactly does <delta> Automation work?

<delta> Automation uses the existing HotFolder application of the ErgoSoft RIP. The HotFolder application was designed to simplify processing and printing standardized images or jobs and reduce operator intervention. By linking a directory on your hard disk to a HotFolder, this directory is then ‘watched’ by the HotFolder application. Images placed into the directory will automatically be processed and printed by the HotFolder application according to the user defined HotFolder parameters. Adding <delta> automation allows the HotFolder to process XML files that identify which image files are to be printed and how they will be processed, including complex instructions such as scaling, crop, step&repeat, color management, and so on.

Imagine an online print shop where a customer may upload images and set parameters for their order such as size, margins or quantity. When the order is placed, the webshop automatically creates an XML specifying the image to be printed with production instructions like size, material, etc. and sends the XML file to the HotFolder where it is automatically processed and printed with the parameters set by the customer.

Once in the HotFolder, the XML file is automatically processed and goes into the regular Ergosoft RIP production pipeline. The HotFolder uses the instructions in the XML file and creates a print job with the set parameters. The print job is passed to the PrintClient and then follows the regular printing pipeline of PrintClient > RIP Engine > Printer to the final output, all with requiring any operator interaction.

What do I need to run <delta> Automation?

Delta Automation requires an Ergosoft RIP Production License with a HotFolder as well as an active license for the Delta Automation Feature itself. Different from other optional features for the Ergosoft RIP, Delta Automation is sold on a yearly subscription model. If you do not yet have an active Delta Automation License but are interested in the feature and want to try it out, get in touch with us through the Form on the Ergosoft Delta Automation page.

Related Articles

Ergosoft Delta Automation XML Basics

Introduction Ergosoft Delta Automation uses the XML markup language to provide a powerful and versatile way for third party applications to interact with the Ergosoft RIP. By creating print jobs in the XML format, third party applications like web ...Delta API

The <delta> webservice is a RIP REST API that uses JSON as a data-interchange format. It uses .NET (Core 6) C#. Each PC hosting an Ergosoft RIP has an independent instance of <delta> installed. The <delta> REST API is connected to the Ergosoft RIP ...Implementation Support through Ergosoft

Implementing Automation can be a complex task. ErgoSoft offers its assistance both in the application of digital printing principles and practices as well as in how to introduce automation to a workflow and how existing workflows can be adapted to ...Exporting XML Reference from Ergosoft RIP

While there currently isn’t a way to directly export entire jobs into the delta automation format, there are several features of the RIP that can be used to generate and export files that use the same syntax as delta automation for use as reference. ...Job

In Ergosoft RIPs, job designates a print unit or a batch of images printed together. Often an order will be printed in one job or multiple orders will be arranged within one job to be printed together. One job has a range of parameters attached to it ...