DripTask Interface

DripTask is the Ergosoft file interface that uses XML syntax to describe already color-managed and pre-ripped print jobs. DripTask print jobs can be submitted via the Ergosoft RIP HotFolder or directly via the Trickle RIP REST API.

Both modules, HotFolder and Trickle, bypass any color management transformation, density linearization correction and dithering algorithm when using the DripTask syntax. Print-ready Ergosoft RIP jobs are created and added to the job queue. Depending on the output device, 1-bit, 2-bit, or 8-bit grayscale print data is required for each device color channel as input defined in the DripTask job. The currently supported file format for such print data is grayscale TIFF with/without LZW compression.

A third-party application interacting with DripTask can obtain all specifications for color settings, bit depth and print area dimensions of each connected output device via the Trickle API.

Input File Requirements

If rastered image data is created on demand, the Trickle API can be used to obtain all the details of the specific Print Environment required to create the pre-color managed and rasterized print job input files for the target printer.

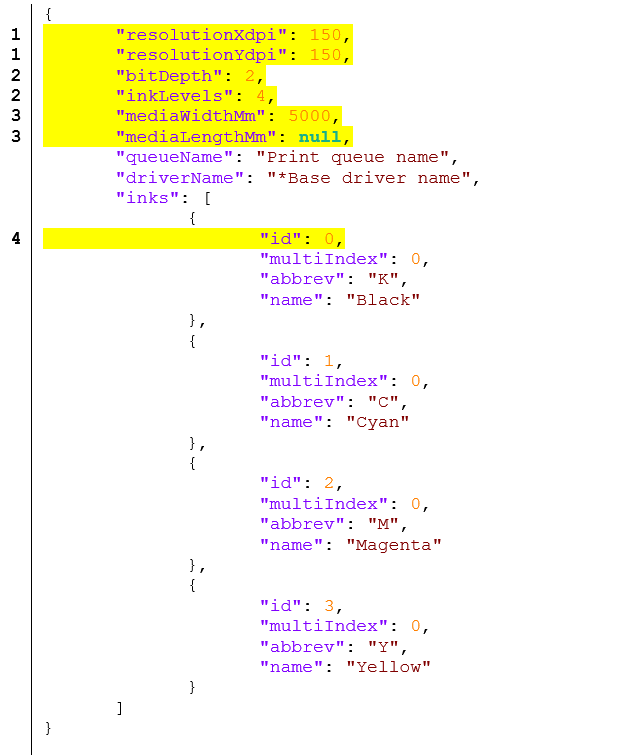

For the API Endpoint / request URL please refer to the Swagger UI. The API will send the response data in JSON Format (See example response below).

The following are the critical parameters that need to be known to create the XML job task and prepare corresponding and correct input print files. Refer to the number in the title to in the example code below to see where the corresponding information is found.

1: X and Y resolution

The resolutions of the input print files (main and extra data) must follow these response values (positive rational number).

2: Number of channel ink levels and print data bit depth

The number of ink levels per channel describes the number of dot sizes (+1, no dot) that the driver uses.

Bit depth defines the data bit depth at which the driver expects the number of dot sizes to be written into the input print data.

3: Maximum printing dimensions

These values define the maximum print width and length/height in millimeters up to which the print job can go to. They are either limited by the driver itself, or further reduced by the media size of the defined media of the target Print Environment.

Note: A response value of NULL means this is a roll-to-roll printer and roll media is loaded.

4: Number of colors and color slot assignments

The inks section lists all active and available colors of the target Print Environment (device) and their order and color ID that must be used in the XML job definition. You can find a table of all Ergosoft channels further down in this article.

Note: A valid print job can only consist of a subset of the available colors received in response.

DripTask Job XML Syntax

With the information on the Print Environment settings in the JSON response above, the raster data can be created. When the data is prepared, a DripTask job in XML Format can be created that refers to the separated raster data and contains job specific information that can then be passed back to Ergosoft using the Trickle API.

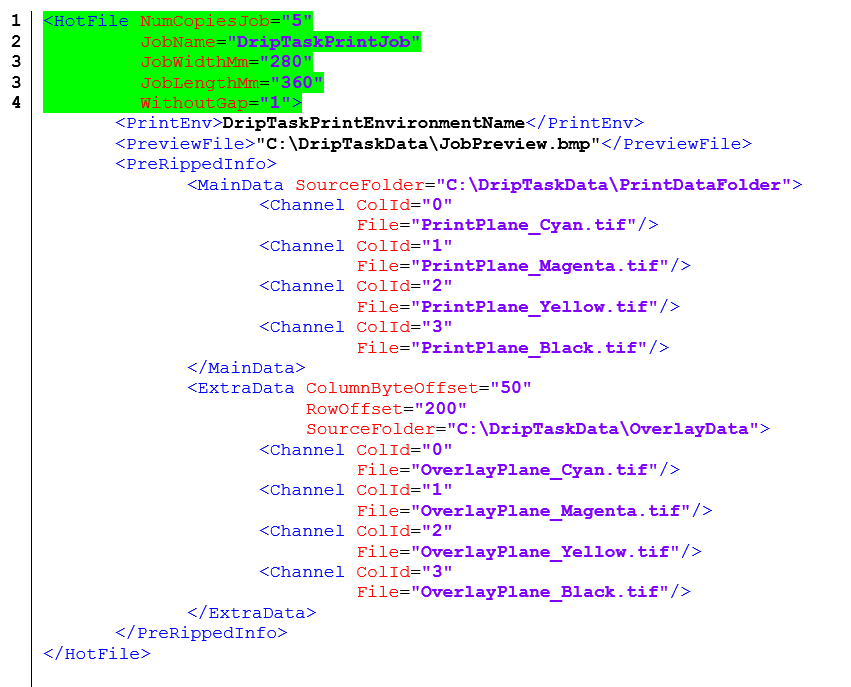

Below is an example of the DripTask XML syntax and how transmit the information.

1: Number of job copies

Input specifications: Positive integer

The tag defines the intended number of job copies to be printed. Depending on the device interface type, the copies are realized by the PrintQueue or transmitted as meta data to the PCS.

2: Job name

Input specifications: Text string

The tag indicates the job name at the time of submission. After the job is created and added to the job queue via the Intra-RIP connector, a local job ID suffix is added to the original name.

3: Print job width and length/height

Input specifications: Rational number

These tags indicate the width and length/height of a print job copy in millimeters. Combined with the number of printed copies, the submitted values are used to calculate media consumption and costs.

In addition, the ratio of X and Y dimensions is also applied to transform the job preview.

Incorrect entries can result in distorted or even missing job previews and inaccurate media consumption records.

The effective print dimensions are ultimately defined by the input resolutions (DPI) of the device/output resolution (DPI) of the pre-ripped print files. Therefore, the print dimensions are not affected by the values of these parameters.

4: Copy print mode

Input specifications: Supported mode ID as integer

Some printers support a so-called seamless print mode of copies. Auto-media feeding, and auto-maintenance cycles between copies are suppressed, if the printer interface allows it.

Supported values:

0 = Without gap not activated. Each copy prints with the default gap of the printer.

1 = Without gap activated. If supported by the interface, copies print without gap.

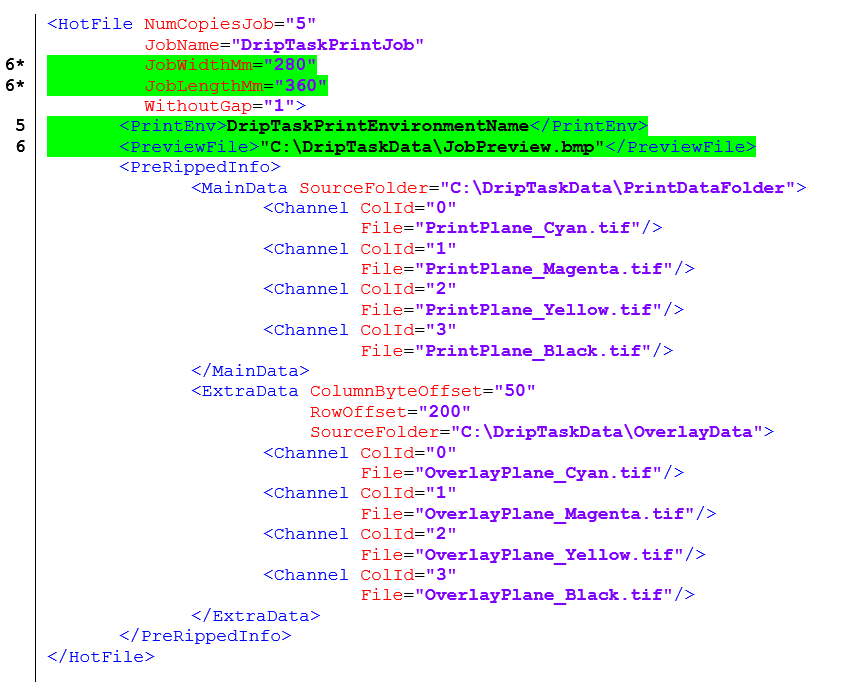

5: Output Print Environment / Driver

Input specifications: Name reference as text string of the target Print Environment

The output device is defined by a name reference to an existing Print Environment of the Ergosoft RIP the printer is connected to.

A Print Environment specifies the required printer port and the device driver it is based on.

Note: When submitting a DripTask job via the HotFolder (not via Trickle API) this Print Environment definition is optional. If defined in DripTask-XML, it overrides the Print Environment set in the HotFolder. If omitted, the Print Environment of the respective HotFolder is used.

6: Job preview

Input specifications: Preview file path including file extension

A job preview can optionally be submitted with a DripTask. The color space must be RGB. The supported input file formats are PNG, JPG, BMP and TIFF.

The job relation of the width and length dimensions (6*) are applied for the transformation of the job preview which is shown in the queues. The pixel size of the longer side of the job preview is going to 256, 400, 800, or 1200px depending on the settings of the User Preferences of the local JobComposer.

The ratio of job width and job length dimensions (6*) is used to transform the job preview displayed in the queues. The pixel size of the longer side of the job preview transformed to 256, 400, 800 or 1200 pixels, depending on the settings of the local JobComposer user preferences.

If the printer driver requires native preview, the submitted job preview file is additionally transformed according to the driver requirements.

8: Channel color identifier

Input specifications: Corresponding Ergosoft channel Color ID

The color identifier attribute defines the color name. The color name slot assignment under the print environment (printing ink assignment) defines the mapping from the input color to the output device channel.

9: Input print file per color channel

Input specifications: File name including file extension

The source folder path including the input file name completes the required input specification per channel.

10: Horizontal offset of overlay

Input specifications: Positive integer

The horizontal offset from the left side of the main data image is specified in bytes. The absolute length measurement of this offset is related to the printer resolution (dpi) and the number of bit depths (e.g. fixed dot = 1 bit per pixel, 3 dot sizes = 2 bits).

11: Vertical offset of overlay

Input specifications: Positive integer

The vertical offset from the top side of the main data image is specified in in number of pixel rows. The absolute length measurement of this offset is related to the printer resolution (dpi).

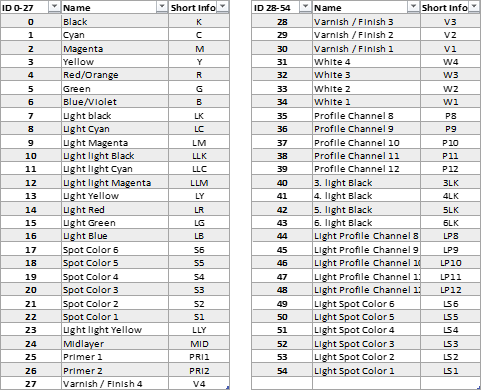

Color Channel Identifiers

To assign files to their appropriate channel we need the correct ID for the color channel (See points 8 and 9 above). The table below lists all available color channels and their respective ID number. This listing corresponds to the available colors in the Printing Ink Assignment tab of a Print Environment in the Ergosoft RIP.

Example DripTask workflow with Ergosoft Trickle API

Below is an example process that describes the steps for fetching the required image format from the Print Environment, creating a four-color print job with five copies and submit as a DripTask via TrickleAPI or HotFolder. For the specific http calls and endpoints to use with the Trickle API, please refer to the Swagger UI as described in the article Ergosoft Trickle API.

Request Print Environment Information

Obtain the names of all installed Print Environments of a system through a http request with TrickleAPI. Use the list to determine which Print Environment you want to create image data for.

Using the Print Environment name, make another http request to get all the details of the specific Print Environment needed to create the print job's pre-color managed and rasterized input files for the target printer.

The response will arrive in JSON Format, below is an example response of a Print Environment:

- X-resolution: 150dpi

- Y-resolution: 150dpi

- Depth: 2-bit

- Ink levels: 4 levels per channel (3 dot sizes plus no dot)

- Max. printing width: 5000 mm

- Max. printing length: NULL = unlimited = roll to roll printer

- Ink ID Channel 1: 0 (=K=Black)

- Ink ID Channel 2: 1 (=C=Cyan)

- Ink ID Channel 3: 2 (=M=Magenta)

- Ink ID Channel 4: 3 (=Y=Yellow)

Note: If the target Print Environment requires TIFF Contone (8-/16-bit) input data, for performance reasons it is recommended to store the Photometric tag as MinIsWhite and the data correspondingly.

Creating the Job Files

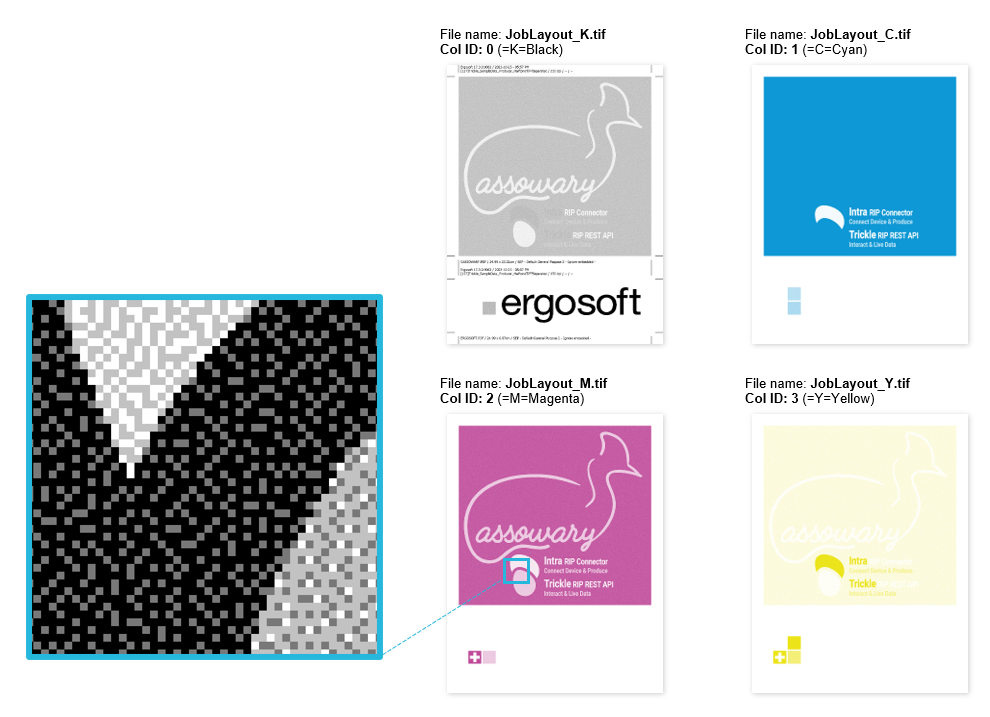

With the Print Environment information, we can create the separated image data in the right format. In this example, the job layout consists of two images arranged above each other.

Based on this layout the job preview file is generated with the following specifications:

- File name: Preview.png

- File format: PNG, ZIP compressed

- Color mode: RGB

- Depth: 8-bit

- Size: 826 x 1074 pixels

Based on the print data requirements for the target printer and its drivers Print Environment, we create the CMYK color input files with the following format:

- File names: JobLayout_{K/C/M/Y}.tif

- File format: TIFF, LZW compressed

- Color mode: Monochrome / Grayscale

- Depth: 2-bit

- X-resolution: 150 dpi

- Y-resolution: 150 dpi

- Job width: 280.42 mm

- Job length: 362.88 mm

This example also uses optional extra data. We overlay a QR code printed only in black with a specified offset. A use case for this might be that we want to use the same main data for every copy, but use a different barcode for every copy. This way we only need to raster the main data once but are flexible with the variable part i.e. the barcode.

Like the main print data, the additional print data must also meet the same print data requirements of the driver's target Print Environment.

- File names: Barcode_{K/C/M/Y}.tif

- File format: TIFF, LZW compressed

- Color mode: Monochrome / Grayscale

- Depth: 2-bit

- X-resolution: 150 dpi

- Y-resolution: 150 dpi

- Job width: 39.96 mm

- Job length: 39.96 mm

Please note that the extra print data for the Cyan, Magenta, and Yellow channels is empty. In this context, white, which corresponds to the ink level of 1, signifies the absence of a print pixel.

Any pixels in the main print data that are beneath a white pixel of the extra data are set to white. This results in a clean white underlay area for the black barcode that is overlaid as K only.

Make sure to place the image data in a location that Ergosoft RIP has access to.

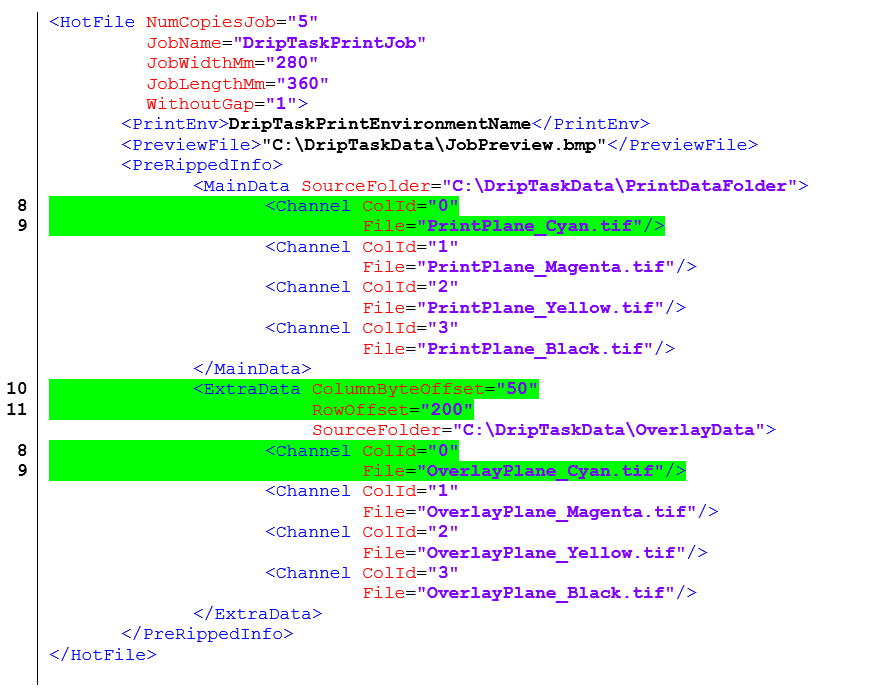

Creating the DripTask XML Job

When we have the image data ready and accessible from the Ergosoft 17 RIP, we can create and transmit the DripTask XML job.

Using the DripTask XML syntax we set up the job and reference the Print Environment to use for output as well as the path for each color channels image.

<HotFile NumCopiesJob="3"

JobName="My First DripTask"

JobWidthMm="280.42"

JobLengthMm="362.88"

WithoutGap="1">

<PrintEnv>TricklePE_Printer_A</PrintEnv>

<PreviewFile>C:\DripTask\Preview\preview.png</PreviewFile>

<PreRippedInfo>

<MainData SourceFolder="C:\DripTask\Main">

<Channel ColId="0" File="JobLayout_K.tif"/>

<Channel ColId="1" File="JobLayout_C.tif"/>

<Channel ColId="2" File="JobLayout_M.tif"/>

<Channel ColId="3" File="JobLayout_Y.tif"/>

</MainData>

<ExtraData SourceFolder="C:\DripTask\Extra"

ColumnByteOffset="50"

RowOffset="200">

<Channel ColId="0" File="Barcode_K.tif"/>

<Channel ColId="1" File="Barcode_C.tif"/>

<Channel ColId="2" File="Barcode_M.tif"/>

<Channel ColId="3" File="Barcode_Y.tif"/>

</ExtraData>

</PreRippedInfo>

</HotFile>

We then use a POST http call or an XML file placed in the Ergosoft HotFolder to submit the job. After a moment, the job will appear in the PrintQueue of the Print Environment we specified inside the code ready to print.

Related Articles

Delta API

The <delta> webservice is a RIP REST API that uses JSON as a data-interchange format. It uses .NET (Core 6) C#. Each PC hosting an Ergosoft RIP has an independent instance of <delta> installed. The <delta> REST API is connected to the Ergosoft RIP ...Error in printing HP Latex Series

Problem/Question You are using an HP Latex Series printer. After starting a print job from the Queue, an error message appears stating that the media information cannot be read. Naturally, you begin to wonder “Why am I getting this error message?” ...JobComposer: The default size of menu and Job & Image Property entries has changed since 17.6

New Default Size for Job & Image Property Icons Since V17.6 the default size of menu and Job & Image Property entries has changed to "Medium". Therefore, new installations of Ergosoft will show 'medium' sized icons, instead of the previous default ...Scanning Barcode

Ergosoft allows you to use Barcode scanning devices or your smartphone to identify jobs in the PrintQueue or CutQueue through a QR code and bring them up for printing. With the Wait for Barcode feature active in the Print/CutQueue, simply scan the QR ...How to Completely Clean Up User Data Folder

Problem/Question What data do I remove to completely clean up my User Data folder? Are there any utilities to help me with this in the Ergosoft Rip? Solution / Workaround SystemGuard is a tool designed to streamline the clean-up and management of ...